Hydraulic filter presses are widely used in various industries for the separation of solids and liquids. They offer several benefits that make them an efficient and reliable choice for filtration processes. Here are some key benefits of using a hydraulic filter press:

1. High Efficiency and Consistent Performance

Effective Filtration: Hydraulic filter presses can achieve high degrees of filtration, effectively separating solids from liquids.

Consistent Output: They provide consistent performance with uniform pressure, leading to predictable and repeatable results.

2. Versatility

Wide Range of Applications: They are suitable for various industries, including chemical, pharmaceutical, food and beverage, mining, and wastewater treatment.

Flexible Operation: Hydraulic filter presses can handle a wide range of materials, from fine particles to coarse solids, and can be used for both primary and secondary filtration.

3. Enhanced Solids Recovery

High Solids Capture: The high-pressure operation allows for maximum recovery of solids, reducing waste and increasing efficiency.

Dry Cake Production: The press can produce dry, compact filter cakes that are easier to handle and dispose of, or even repurpose, depending on the industry.

4. Cost-Effective Operation

Low Operating Costs: Hydraulic filter presses have relatively low operating costs due to their simple mechanical design and low energy consumption.

Reduced Waste Disposal Costs: By effectively recovering solids and producing drier cakes, the costs associated with waste disposal are minimized.

5. Improved Quality of Filtrate

Clear Filtrate: The high-pressure filtration process ensures that the filtrate is clear and free of fine particles, which is crucial for industries requiring high-purity liquids.

Consistent Quality: The ability to maintain consistent filtration pressure results in uniform filtrate quality.

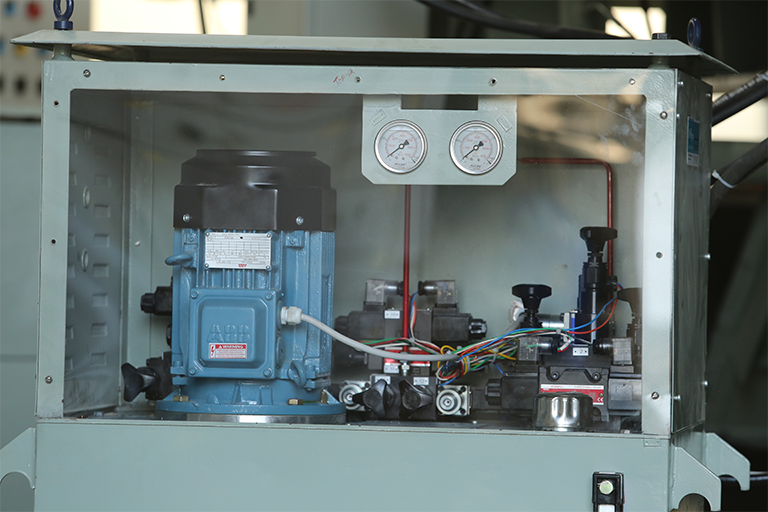

6. Automation and Control

Automated Operation: Many hydraulic filter presses come with automated features, such as automatic plate shifters, PLC controls, and sensors, which reduce the need for manual intervention and increase operational efficiency.

Precise Control: Operators can precisely control pressure, cycle times, and other parameters, optimizing the filtration process for specific applications.

7. Durability and Reliability

Robust Construction: Hydraulic filter presses are built with durable materials that can withstand high pressures and harsh operating conditions.

Long Service Life: With proper maintenance, they offer a long service life, providing reliable performance over many years.

8. Environmental Benefits

Reduced Waste: By maximizing solids recovery and producing drier filter cakes, hydraulic filter presses contribute to waste minimization.

Water Recycling: In many processes, the clear filtrate can be reused, reducing the overall water consumption and promoting sustainable practices.

9. Space Efficiency

Compact Design: Hydraulic filter presses are relatively compact compared to other filtration systems, making them suitable for facilities with limited space.

Stackable Plates: Some designs allow for stacking filter plates, which can further save space and increase filtration capacity within the same footprint.

10. Safety Features

Safety Mechanisms: Modern hydraulic filter presses are equipped with safety features such as pressure relief valves, automatic shutdown systems, and protective guards, ensuring safe operation.

By leveraging these benefits, industries can enhance their filtration processes, achieve higher efficiency, reduce operational costs, and improve overall product quality.